Sharpen Your Saw

Learning Modules for Lean Six Sigma Practitioners, Project Managers, and PMOs

“Sharpen your saw” is the 7th habit identified in Stephen Covey’s book, The 7 Habits of Highly Effective People. In the book, Covey tells a story of someone walking in the woods who comes upon a logger busily sawing down a large tree. Several trees have already been felled nearby. The logger is sweating profusely in the heat, appears exhausted, and yet continues to work.

Finally, the walker asks the logger about his chore. “Can’t talk … now,” the logger says, gasping between words. “Gotta … get these trees … cut down.”

The walker politely suggests that perhaps the saw has become dull from overuse, and it might help to stop and sharpen it.

“No time to … sharpen the saw,” replies the logger. “Too … busy … cutting trees!”

We’re probably not quite as stubborn about our chosen work as Covey’s allegorical logger. However, all of us need to look up from the tasks at hand from time to time and become aware of new, different, and better ways to perform the job.

The message of the “Sharpen Your Saw” series is this. Take time for reflection and self-improvement, and to learn new things to help improve your professional and personal effectiveness. The ‘Sharpen Your Saw‘ posts each relate a Project Management or Lean Six Sigma tool or method that you can learn and apply today to make your projects run more smoothly.

Newest Learning Modules on Top

How one manufacturer used Lean Six Sigma to effect major improvement in production metrics rapidly, after a difficult new product start-up.

Your project encounters an unexpected problem that blows up your schedule, creating massive NVA. Restore the project ‘flow’ using three process improvement techniques.

Work to eliminate the NVA of Unused Talent first. Then your entire team can expand their knowledge by tackling the other seven types of NVA.

A survey of PMs reveals the kinds of problems they face while running their projects. Do these 3 recurring themes echo your experience?

Why is Inventory considered waste or NVA? From a lean six sigma perspective, it slows the creation of customer value. Here are some steps you can take to help hold the line.

Waiting NVA affects nearly every business process, slowing creation of customer value and piling on implicit costs. Don’t wait – address it now!

Learn to eliminate defects at the source, and to eliminate extra processing resulting either from defects (rework, reprocessing) or from causes such as collecting just-in-case data.

PMs and teams focus on solving problems down to the root cause. Developing lasting Corrective Actions is the critical final step for high-performing teams.

Use Daily Stand-up with PDSA or Agile Kaizen to get your project status out of the RED and back to GREEN.

Don’t only study what went awry. Good outcomes need to be understood too. Build them into your firm’s best PM practices.

Your test strategy needs to do more than just flag defective units. For order of magnitude quality improvement, graduate from Find Defect, Fix Defect, to Root Cause, Corrective Action.

The key to schedule recovery is discovering the need early, and then taking the right actions quickly.

How driving higher quality leads to lower direct costs –

You’re welcome, Ms. or Mr. Operations Director and CFO.

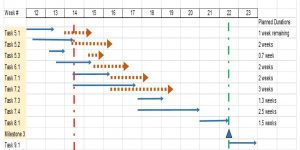

Set and monitor schedule milestones in a meaningful way, to keep your team, your manager, and your customer satisfied.

It’s a continuous improvement learning journey, not a quick-fix event. Some practical steps to keep your business on track.

Improve value to your customers. Focus on Value-Add (VA) activities, and cut out the 8 Non Value-Add (NVA) Lean Wastes.

Reports can lead you astray. Go to the Gemba – the place where work is done – if you can handle the truth.

Here’s a data-driven, fact-based method for getting to the root cause of many types of business problems.

To grow as a Program Manager, practice these four techniques and work to get better at them.

A newly-promoted Program Manager faces the schedule planning challenge for the first time.